From semi-automatic to fully intelligent industrial-grade fastening systems, we deliver a comprehensive matrix of screwdriving equipment, providing flexible and high-precision intelligent assembly solutions for global manufacturers. Empowered by our proprietary 3rd-gen dynamic compensation technology, our systems achieve a 99.9% product yield rate standard while boosting client productivity by over 40%.

Core Value Propositions

Full-Spectrum Technical Coverage: Compatible with M1.0-M8.0 screw specifications

Smart Manufacturing: Equipped with AI vision positioning systems and IIoT platforms enabling real-time production data visualization

Deep Customization: Delivered screw fastening solutions across 12 sectors including 3C electronics, automotive components, and renewable energy equipment etc

Kingdom delivers high-quality automatic screwdriving systems for a wide range of possible applications in series production. Combining AI-powered process control with ISO-certified precision, our machines boost productivity by up to 40% while maintaining 99.9% defect-free output. Key strengths:

Plug-and-play operation with intuitive HMI interfaces

Real-time IoT diagnostics enabling predictive maintenance

UL/CE-compliant safety with collision avoidance systems

Energy-saving designs reducing TCO by 25% vs competitors

Scalable for both compact workshops and high-volume plants, our solutions ensure seamless integration with Industry 4.0 ecosystems while eliminating retraining costs through adaptive automation.

CE/UL/ISO-certified safety & quality, compliant with EU/US industrial regulations

±0.05mm repeat positioning accuracy

AI-driven torque control reduces defective rate to <0.1%

Energy-efficient design cuts power consumption by 25%

Predictive maintenance via IoT real-time monitoring

Modular design adapts to M1-M6 screws without retooling

Seamless integration with ERP/MES systems

100+ OEM partners in automotive/electronics sectors

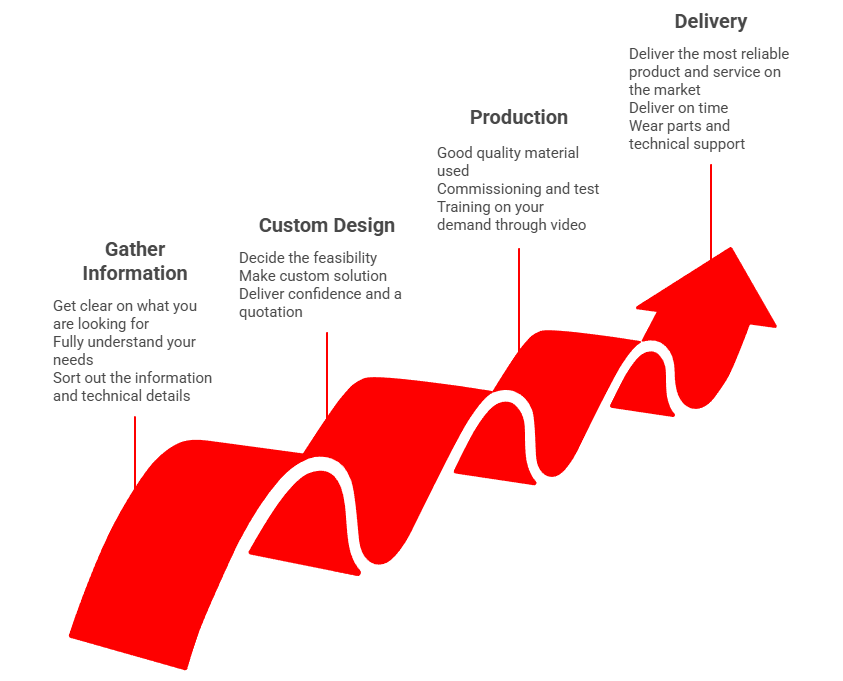

Our Optimized Workflow Simplifies Your Work