Our quality commitment begins before production.

100% Raw Material Screening: Incoming metals and electronic components are tested for hardness, dimensional accuracy, conductivity and performance

Supplier Vetting: Only ISO 9001-certified suppliers qualify for our Approved Vendor List

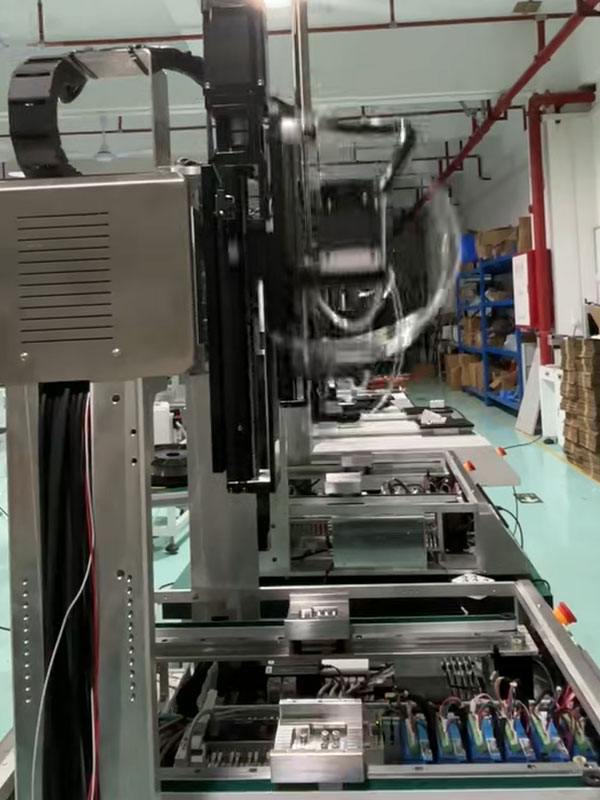

Every screwdriving machine starts with failure-proof engineering.

Patent-Protected Tech: 15+ patented systems

R&D Team: 5 engineers with 10+ years’ automation expertise.

Component integration follows military-grade protocols.

Critical Checkpoints:

Torque calibration for spindle motors (±1% tolerance).

Vision system alignment with 0.02mm repeatability.

Assembly Team:

10+ technicians, each trained for 120+ hours.

No machine leaves our factory without surviving our gauntlet.

48-Hour Endurance Test: Continuous operation at max speed (e.g., 60 screws/minute).

Smart Fault Simulation: AI-driven scenarios to validate error recovery.

Test Metrics Tracked: Torque consistency, noise levels, energy consumption.

Your machine must earn its certification.

32-Point Checklist: Covering function, safety (CE/UL), and cosmetic integrity.

QC Sign-Off: Dual approval by lead engineer and QA manager.