Engineered for both sophisticated automation platforms and versatile robotic arms, Kingdom automatic screw feeding system seamlessly transitions between manual and automated operation. Our auto screw feeder machine expertly handles specialty screws, ultra-short 1:1 screws (length equal to diameter), and screws with washers. Designed for efficiency, its compact size minimizes workspace footprint, significantly reducing operator fatigue while boosting productivity and lowering costs. Featuring an imported high-torque brushless motor, intelligent anti-interference control, multi-signal interfaces, and an intuitive digital control panel with quick-set buttons for instant parameter adjustment;

We also offer customized screwdriver with automatic screw feeder solutions – simply tell us your individual application, and we'll tailor the perfect unit for your needs.

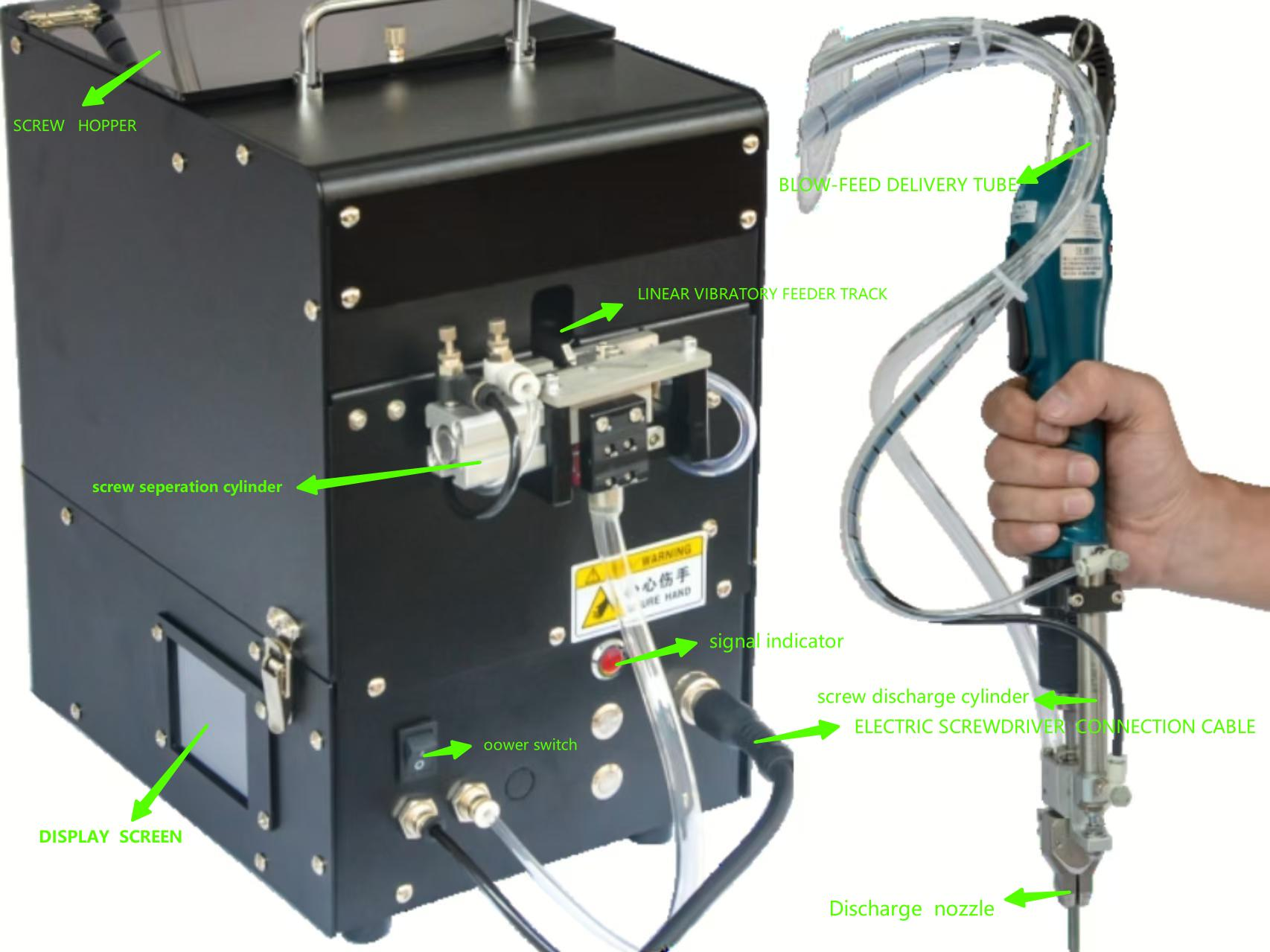

This automatic screw feeding system integrates mechanical transmission and computer-controlled automation. Utilizing horizontal vibratory feeding - where screws are positively aligned through linear vibration - handheld automatic screwdrivers fundamentally differ from gravity-fed systems. This advanced methodology reliably handles washer-equipped screws and specialty fasteners while eliminating jamming risks for ultra-reliable operation.

Kingdom self-feeding screwdriver applicable to the following screws :

The Kingdom Automatic Screw Feeding System is engineered for precision and efficiency, making it a top choice among automatic screw feeder suppliers for industries like automotive and electronics. Below are its key features, designed to enhance assembly processes.

Broad Compatibility. The automatic screw feeder supports a wide range of fasteners, including screws, nuts, and studs, and integrates seamlessly with various screwdrivers, controllers, and handling systems. This versatility makes it ideal for diverse production lines, eliminating the need for costly modifications.

Flexible Stroke Modules. With multiple stroke options, the self feeding screwdriver enables tightening in any direction—vertical, horizontal, or angled. This adaptability suits complex assemblies, reducing setup time and enhancing efficiency for varied applications.

Precision with Optional Functions. Optional Dynamic Reaction Torque ensures accurate torque control, while online calibration maintains consistent performance in the automated screw feeder. These features minimize errors in high-precision tasks, ensuring reliable results.

Versatile Feeder Options. The system offers a choice between a step feeder for larger fasteners or a bowl feeder for high-speed sorting under the RAPID configuration. This flexibility optimizes delivery for specific production needs, making it a standout auto screw feeder machine.

Specialized Loading Heads. Equipped with auto-feeding, vacuum, and pick-and-place heads, the system ensures precise screw placement in standard, hard-to-reach, or unique assembly scenarios, enhancing the capabilities of the automatic screw feeding system.

Simplified Integration. An optional pneumatic panel and logic control streamline automation, supporting programmable sequences for seamless integration into smart manufacturing setups. This makes the system a key component in assembly automation screw feeders, boosting productivity.

| Power supply | AC100V~240V DC12V |

| Output Power | DC24V/1200mA |

| Noise | <30 dB |

| Outline dimension | 284x184x334mm (L*W*H ) |

| Weight | 11KG |

| Feeding speed | 50-100pcs/min |

| Screw hopper volume | about 1000-3000PCS |

| Feeding distance | 1-4m |

| Efficiency | 50-100pcs/min |

| Applicable screw size | M1.4-M5.0 |

| Applicable screw lengths | ≤20mm |

The automatic screw feeder features a high-end aluminum alloy housing with an ergonomic grip, ensuring operator comfort and durability during assembly automation screw feeders applications.

Certified for anti-magnetic interference (EMI < 10V/m per IEC 61000-4-3), the auto feeder screwdriver ensures reliable performance in sensitive environments, making it ideal for automatic screw feeding system setups.

With a 50,000-hour MTBF, the automatic feed screwdriver combines a brushless motor with aerospace-grade bearings, offering longevity for auto screw feeder machine operations.

The automatic screw feeding machine leverages self-optimizing torque/rpm settings via machine learning algorithms, enhancing precision in self feeding screwdriver applications.

Featuring a real-time TPM display with one-touch preset recall for torque, rpm, and count, the screwdriver with automatic screw feeder simplifies operation for automatic screwdriver feeder users, ensuring efficiency and ease of use.

3C Electronics: The automatic screw feeder excels in PCB assembly and micro-screw fastening, providing precision and efficiency for assembly automation screw feeders in the electronics industry.

Home Appliances: Designed for high-volume production lines, the auto feeder screwdriver ensures seamless operation in automatic screw feeding system setups for home appliance manufacturing.

Auto Components: The automatic feed screwdriver supports EV battery module assembly and interior trim production, offering reliability for auto screw feeder machine applications in the Lillian.

Precision Toys: With the automatic screw feeding machine, miniature mechanism assembly for precision toys is streamlined, making it ideal for automatic screwdriver feeder tasks requiring intricate fastening.