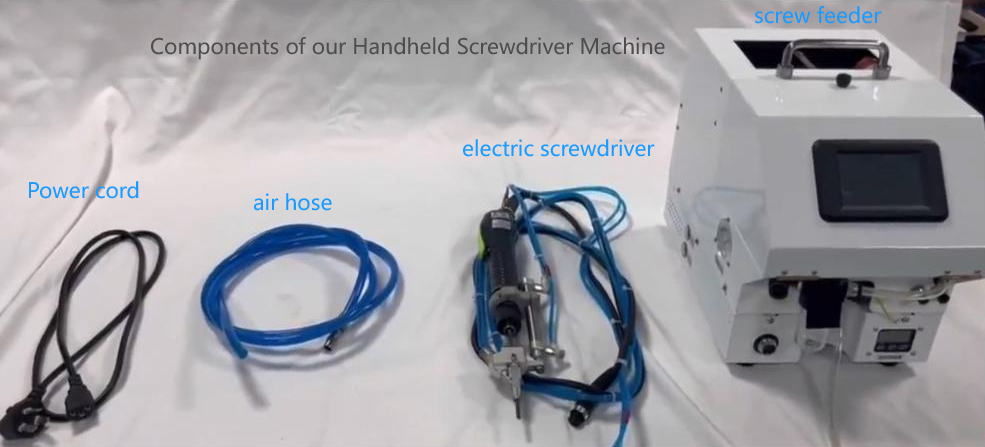

Kingdom Semi Automatic Screwdriver features a compact, space-efficient design ideal for screw fastening on flat surfaces and in shallow holes. Its lightweight electric driver delivers practical operation, complemented by a 4.3-inch touchscreen with intuitive HMI. Key functions include screw counting, parameter configuration, and I/O monitoring – with universal compatibility for all screw materials.

Kingdom semi auto screwdriver delivers versatile performance across multiple sectors, including electronics, automotive assembly, medical device manufacturing, and drawing board assembly. By replacing manual screwdriving processes, it boosts operational efficiency by up to 300% while maintaining defect rates below 0.3%, making it a preferred choice for leading manufacturers worldwide.

The semi automatic screwdriver revolutionizes drawing board assembly, delivering up to 300% faster performance than traditional manual methods while maintaining exceptional precision with defect rates below 0.3% (3 PPM). Engineered for high-efficiency production, this screwdriver for drawing board assembly supports over 2,000 fastening operations per shift, making it ideal for assembling adjustable drafting tables, easels, and other creative workstations. With a 12-month payback period, this tool offers outstanding ROI for industries like furniture manufacturing and electronics.

Designed for versatility, the semi auto screwdriver works seamlessly with wood, metal, or composite boards. Its ergonomic design and auto-feed mechanism reduce operator fatigue and wrist strain, while quick bit changes ensure compatibility with various fastening tasks. Energy-efficient and low-maintenance, this tool enhances productivity and quality in demanding assembly environments.

Speed and Efficiency: The semi auto screwdriver accelerates drawing board assembly tasks by 300% compared to manual screwdrivers, boosting throughput.

Precision and Reliability: Achieves defect rates below 0.3% (3 PPM) for consistent, high-quality results in every project.

Versatility: Compatible with diverse materials and applications, from drafting tables to intricate setups, making the screwdriver for drawing board tasks highly adaptable.

Operator Comfort: Ergonomic design and auto-feed system minimize fatigue and improve workflow during extended use.

Cost-Effective: Offers a 12-month ROI with low maintenance and energy-efficient operation, ideal for cost-conscious production lines.

When selecting a semi automatic screwdriver for your production line, consider factors like bit compatibility, torque settings, and ease of maintenance to ensure it meets your specific drawing board assembly needs. This screwdriver for drawing board assembly is a game-changer, combining speed, accuracy, and durability to elevate your production process.

| Power supply | 220VAC /50HZ |

| Outline dimension | 254x344x265mm (L*W*H ) |

| Weight: | 15KG |

| Applicable screw sizes | M2.0-M5.0 |

| Applicable screw lengths | ≤20mm |

| Feeding speed | 0.35s/pc |

| Screw hopper volume | M3.0*3000PCS |

| Feeding distance | 1-3m |

| Efficiency | 50-70pcs/min |

Cross-Industry Compatibility. The semi automatic screwdriver offers universal application across electronics, automotive, medical sectors, and specialized tasks like screwdriver for drawing board assembly. It supports all screw materials, including stainless steel and aluminum, ensuring flexibility for diverse production needs.

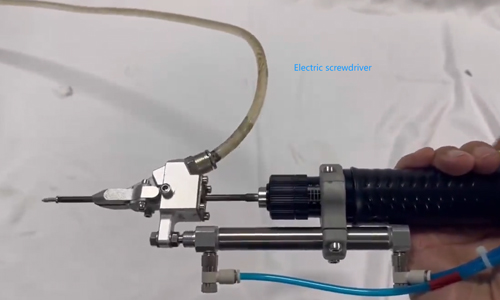

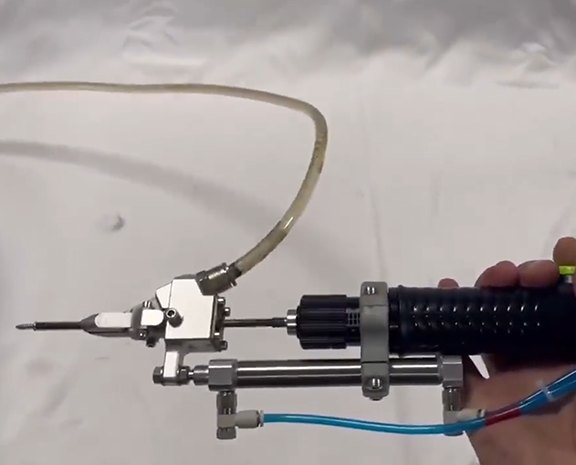

Optimized Ergonomic Design. Featuring an ultra-light electric driver with a vibration-dampened grip, the semi auto screwdriver ensures operator comfort and reduces fatigue during extended use in drawing board assembly and other applications.

Space-Efficient Architecture. With a compact footprint, the semi automatic screwdriver fits seamlessly into confined assembly stations, making it ideal for space-constrained environments like those used for screwdriver for drawing board tasks.

Intelligent Control System. Equipped with a 4.3" industrial touchscreen and an icon-based HMI (IP54 rated), the semi auto screwdriver provides intuitive control for streamlined operations in drawing board assembly and other precision tasks.

Precision Process Control. The semi automatic screwdriver includes real-time counting, torque profiling, I/O diagnostics, and data logging, ensuring precise and reliable performance for applications like screwdriver for drawing board assembly.

Premium Quality Output. Achieving a defect rate below 0.3% (validated per ISO 14644 cleanroom standards), the semi auto screwdriver ensures high-quality output for drawing board assembly and other critical manufacturing processes.

Minimal Training Requirement. With single-button operation and an error-proof guidance system, the semi automatic screwdriver simplifies training, making it accessible for operators working on screwdriver for drawing board tasks and beyond.

Unmatched ROI. Delivering 300% faster performance than manual operations with a 12-month payback period, the semi auto screwdriver offers exceptional value for drawing board assembly and other high-efficiency production environments.

Demonstrating exceptional performance in drawing board assembly, our semi auto screwdriver delivers high cost-effectiveness and cross-industry versatility. This case study confirms the semi automatic screwdriver's capability to enhance production efficiency while maintaining defect rates under 0.3% (3 PPM), achieving over 2000+ consistent fastening operations per shift in screwdriver for drawing board applications.